The PJLT: Pararescue's Most Popular CSAR Knife

More

More about this PJLT

On this page, you will read topics about my most popular tactical combat search and rescue knife, the PJLT (Pararescue

Jumper LighT). There are captioned thumbnail photo boxes, and if there is an associated page to that photo with more

information, photographs, and details, they will be linked in blue.

Thanks for being here and thanks for supporting our

military, rescue, and law enforcement professionals who make it possible

for us to love the life we live in the United States of America!

Jay,

This is Jared Lay; my family has bought several knives from you. I bought my brother, Jeremiah Lay, a PJLT

Shank knife for him when he graduated the fire academy. Well, long story short, my brother uses the knife

all the time and just had it with him in the Philippines, after the destruction. He went into some areas

for rescue that were the first rescue people in. Just wanted you to know we love the knives you have

made and that they are doing great work across the world.

--Jared Lay

Over a 25 years ago, a small group of men dressed in battle dress

uniform rang the doorbell of my knife shop and studio in Magdalena, New

Mexico. They told me they were conducting tactical training exercises twenty

miles north of the village, in a remote part of the South Central New Mexico

badlands. They were PJs.

PJ is the acronym for Pararescue Jumper, the short

name version members of the United States Air Force Pararescue. This

highly trained soldier-paramedic-rescue service consists of

some of the finest men in our military, indeed some of the finest

men in our country. They expend incredible amounts of

training, endurance, education, practice, and trials to

become the guys who go behind enemy lines to rescue other

men. USAF Pararescue is, simply, our best and finest

military combat rescue service.

PJs are also asked to perform rescues in civilian

emergency crisis situations. When civilian rescues

are more than civilians can handle, and are where civilian rescue

services can't go, USAF Pararescue will be there, answering

the call. They do this so that others may live.

When this elite group of men asked if I could make

some knives, some very special knives, I was deeply

honored to give them my best. They worked with me to design

their dream knives that they would use and carry in the

field. It started with a small group

of knives: the Paraeagle, the Creature, the

SERE Kid, and

the large PJ as the initial knives designed by active duty

Pararescuemen for their use in combat and rescue. Of these four, the

PJ was

created to be a large and imposing tanto-bladed weapon and

tool, with substantial size and meat for heavy use. Though

the large-sized PJ was and still is a very popular

knife design with military, rescue service, professionals,

and collectors, I took it upon myself to design a smaller,

lighter version, that was easier to carry, yet had some of

the same great features, components, and geometry of the larger

knife. From these earlier designs, I created the PJ LighT,

or PJLT.

As soon as I finished the first PJLT, I knew I had a hit.

This was a substantial knife, toughly designed with just the

right geometry and balance to be extremely useful, reliable,

and a worthwhile adjunct to the rescue service skill, while

retaining the characteristics to be a viable and formidable

weapon when needed. With the addition of some useful

features like my vampire rip-teeth serrations and top length

spine swages, the PJLT has proven itself in the field of

combat, service, and rescue across the wide range of

tactical and rescue service. While being Pararescue's most

popular knife, it has also become a favorite of SWAT team

members, Emergency Response Units, Law Enforcement, and even

Hazardous Materials professionals.

With the history, design, and reputation of the PJLT, it

is not surprising that it is my most popular knife overall.

I make more PJLTs than any other knife in my pattern inventory of

over 400 patterns.

The PJLT is clearly a fine knife, originally designed for

CSAR and utility use, a knife that has become a necessity

for many well-equipped professionals, valued by collectors,

and depended on by knife users and enthusiasts.

Page Topics

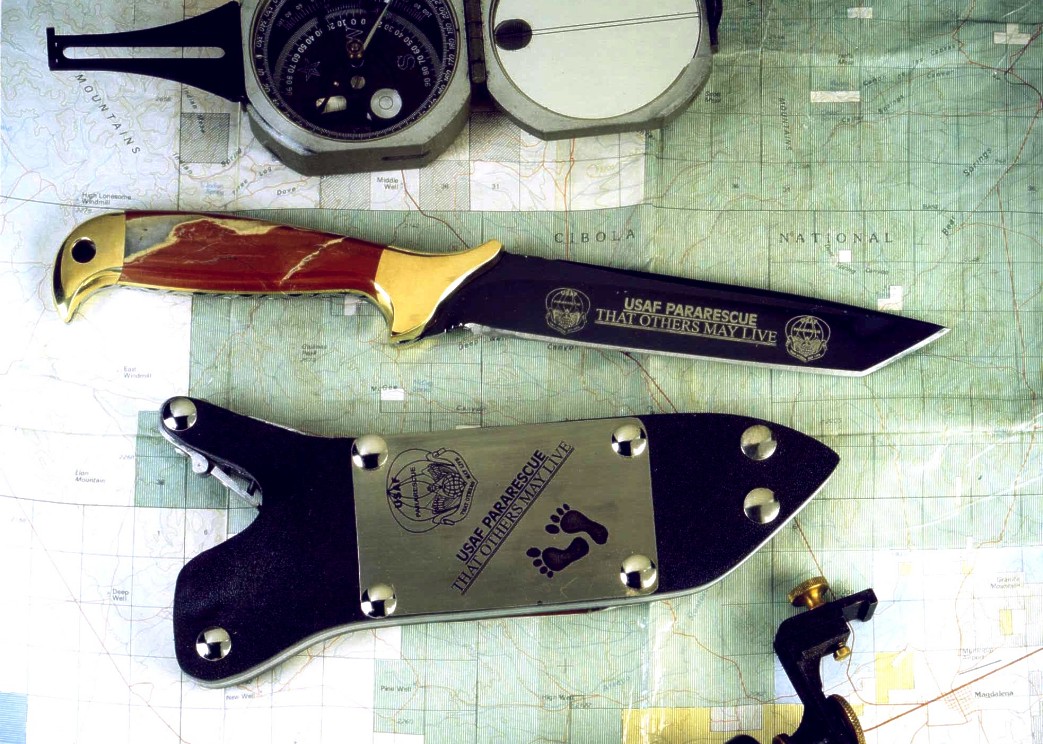

PJLT Commemorative

USAF Pararescue Knife

"My sheath held my knife in place at all times... On one mission when

rappelling into a hot HLZ with a 70 lbs pack I went upside down and got

drug when the Helo decided to spilt, my knife was there.

Jay, I know of no other knife that you made that have seen so much action. From the

first ever Jump mission conducted at the PJ School to the 2 OEF

deployments 23 Combat missions in all; not to forget multiple peace

time missions. When my life depends on my knife why carry anything but

the very best. Thanks for building the best for the best."

--SZ (Super), USAF Pararescue

More

More about this PJLT

- The Blade: The PJLT can best be described as a tanto-bladed

tactical knife. It is medium-sized in the range of knives I make,

but don't think that it is small or not up to the task. The blade lengths are typically six inches measured

from the point to the front bolster face, which offers significant knife reach.

- The Primary and Secondary Point: The tanto point has two

distinct angles of cutting edge, which creates two

distinct point profiles. The primary point is the typical

tip of the point, and the secondary point is located where the two

cutting edges converge. Because it is designed with wide

angles, the primary point has a wide geometry with

significant metal to support the point when thrusting or

piercing. With the secondary point, the user can bear down

on the spine of the knife with the heel of his hand and

apply tremendous pressure that he would not be able to apply

in any other blade shape when cutting through tough textiles

and materials. Because there are two distinctive points, the

primary point can be preserved for sharpness and piercing

while the secondary is used for more demanding applications.

Due to the geometry at the union of the two linear edges at

the secondary point, this point is physically stronger than the

primary point.

- The Cutting Edges: The edges of the

PJLT are straight. Without complex curves, the knife is more

easily held at the correct and uniform angles against the

stone to apply and maintain accurate angles to produce a

superior cutting edge. These days, I start most PJLTs with a

single bevel cutting edge, but the knife owner can easily

adapt a double bevel cutting edge as recommended by

Juranitch's course in

Razor Edge Sharpening for a durable,

dependable cutting edge.

- The Hollow Grinds: This knife blade is

deeply hollow ground and the grinds are well-matched and

accurate. They are thick enough to be durable and thin

enough for a low sharpening angle and increased blade

longevity. That means that the geometry of the grind creates

a thin and significantly sharp cutting edge because the

knife blade is not thick like a flat grind or a convex

grind. Because the hollow grind is thin into the midline of

the knife blade, resharpening is easier, and the longevity

of the knife blade is great even after repeated sharpenings.

This is a knife that can last for generations. The hollow

grinds are terminated with sweeping curves so mechanical

blade-to-handle stresses are distributed across a wide area

of the ricasso. The primary point grind is also hollow

ground, at a slightly thicker geometry so that the point is

physically strong.

- Serrations: Though some PJLTs are made

without serrations, most of my clients request the

typical two inches of my vampire rip teeth serrations at the

ricasso. These serrations have developed from my military

client's original requests of having rip teeth that work,

even if broken off. Too many manufacturers make serrations

that are decorative only, and they wanted the most

aggressive serrations possible. My vampire serrations are so

named because they have alternating radius cuts into the

hardened edge of the knife blade, creating a varying

geometry and point set that can improve the ripping ability.

The serrations are cut at a very low angle, creating

extremely aggressive points at the confluence of the grinds.

These points dig deep into textiles, hardwood, bone, and a

wide variety of materials that make them extremely useful.

They are diamond ground for a crisp, clean geometry and are

not washed-over or rounded.

- Thumb Rise: The PJLT has a modest thumb

rise incorporated into the spine of the knife blade. This

gives purchase for the thumb when held in a forward saber

grip, stabilizing the grip while helping to prevent the hand

from sliding forward. The thumb rise can also offer control

with the thumb over the front of the rise, for more

controlled cutting tasks. The thumb rise also offers an area

for the lock tang set if the knife is equipped with a

locking sheath.

- Full Tang: The PJLT is a full tang

knife, one solid piece of steel from the tip of the point to

the butt of the handle. This is the strongest arrangement

for an extreme use knife and offers tremendous strength at

the ricasso, where the blade and handle meet. There simply

is no stronger blade to handle geometry than the full tang.

- Blade Materials: Most of the PJLTs I

make are in 440C (SAE 51440C) high chromium martensitic

stainless tool steel, the same steel used to make corrosion

resistant ball bearings, valve seats, and tools. This steel

is usually chosen for the PJLT because it is durable and

wear-resistant, yet is highly corrosion resistant for marine

and wet exposures. It can be field sharpened, though it is

harder to sharpen than most other tool steels, and is

reliable with a long and proven reputation. Some of the

clients request the slightly tougher ATS-34, or the more

wear resistant CPMS30V (which usually can not be field

sharpened). I can make the knife in any steel my clients

request.

- The Fittings: The fittings of this knife are the

bolsters, handle pins, and lanyard tubes.

- The front bolster is designed to bolster the

blade-to-handle junction, strengthening the entire

knife while offering a wide area for the forefinger

quillon to help lock the hand into the handle and

prevent the hand from sliding forward onto the

blade. It also widens the area at the thumb for

applying pressure to bear down on the knife's

cutting edge. The front bolster also aids in bedding

and physically locking the handle scales to the

blade, as the bolsters are accurately dovetailed.

- The rear bolster strengthens

the butt of the knife handle. The rear bolster has a

substantial hawk's bill quillon shape to offer an

area to pull when extracting from the knife sheath

and to lock the hand into the handle for grip

security. The rear bolster is substantial enough for

light impact, and typically has a lanyard hole that

extends completely through both rear bolsters and

through the tang of the knife handle. Many clients

provide their own personalized lanyards depending on

their service duty, use, or requirements. The

lanyard holes are chamfered to minimize rubbing and

wear of the lanyards. Like the front bolster, the

rear bolster is dovetailed to help bed the handle

scales and strengthen the entire handle.

- Lanyard Tubes: When a PJLT is

requested that does not have a rear bolster (for

lighter duty and a decreased weight), a lanyard tube

is used to prevent splitting or wear of the handle

materials. It is of the same metal as the bolsters

and other fittings, and is chamfered and dressed to

minimize rubbing and wear of the lanyard.

- Pins: The typical arrangement

of the PJLT calls for pins securing the handle

scales. The pins are the same material as the

bolsters, and are through the entire tang and both

handle scales for mechanical security. Multiple pins

are used instead of few for greater strength,

durability, and longevity. The pins are set in zero

clearance holes for stability and prevention of

infiltration of contaminants.

- Materials: Though the PJLT is a

custom knife and any material can be requested for

the bolsters, pins, and handle fittings, mostly I

use 304 austenitic stainless steel. This is a high

nickel, high chromium stainless steel and the same

material used on most stainless steel bolts and

fasteners. While many other makers use 416 stainless

because it's easier to machine, it is not as

corrosion resistant, hard, or tough as 304. 304

stainless steel is a zero care stainless. I can also

use naval brass, nickel silver, or other metals per

client's request.

- The Handle: The handle of the PJLT

is a full tang handle; it's construction is typically

two handle scales attached to the sides of the knife

blade tang, secured by the dovetails on the bolsters,

the through-tang pins, and a high quality polyepoxide

thermoset adhesive. The handle scales are solid, secure,

and permanently bedded to the handle and sealed against

moisture and contaminant infiltration. The tang of the

PJLT is fully tapered properly milled for weight balance

so that the knife is not handle heavy, even when using

higher-mass handle materials like gemstone. The handle

is contoured and nicely shaped for comfort, and blended

with the bolsters for uniformity. The handle is not too

bulky, and in the standard configuration can accommodate

most hands, even gloved.

- Micarta Phenolic: Most of my

PJLTs have micarta phenolic handle scales. Micarta

is the trade name for a fine phenolic thermoset plastic, which

is waterproof, lightweight, and extremely tough and

durable. The phenolic can be impregnated paper,

linen, or canvas for increased strength and texture.

It is available in a variety of colors and textures.

Mostly, I use heavy canvas reinforced micarta

phenolic in black, and when bead blasted it offers a

distinctive gray pattern and texture that feels

secure to grip.

- G-10: This is a fiberglass-epoxide

thermoset industrially manufactured material

that is harder than micarta and offers a more

distinctive color pattern. It has most of the same

properties as micarta.

- Exotic Hardwoods: There are

numerous options of hardwood that are durable enough

and have high duty reliability to use on the PJLT,

for those who prefer the warmth and character of

wood. I only use the harder, heavier types for this

tactical knife.

- Gemstone: I frequently make

PJLTs with gemstone handles, some are even in

combat. The gemstones I use are hard, tough, and

extremely durable, requiring no care. Many of my

investment grade PJLTs are handled in gemstone.

- Horn, Bone, and Ivory: Because

these are somewhat porous materials and of limited

durability, I do not make the PJLT with this type of

handle.

- The Finish: How a PJLT is finished

depends on the blade steel, the handle and fitting

material, and the handle material. Most of my PJLTs are

bead blasted for a flat, non-glare finish if they are to

be use in tactical exposures, but some clients request

mirror finish for a lower care factor, higher corrosion

resistance, and greater long-term value.

Page Topics

PJLT Commemorative

PJLT, Reverse view

More

More about this PJLT

The PJLT was originally designed as a light Pararescue CSAR (Combat

Search and Rescue) knife with tactical combat applications. It has found

favor across many fields, from civilian rescue organizations,

firefighters, SERE (Survival, Evasion, Resistance, and Escape)

specialists, law enforcement and SWAT (Special Weapons and Tactics)

teams, combat infantrymen and even professional smokejumpers. I've made this knife for

a wide range of specialists and knife enthusiasts, and even made several

in collector's grade, materials, embellishment, and finish.

The main directive of the PJLT is and always will be

United States Air Force Pararescue, and the knife has even

found favor with the instructors at the PJ school at

Kirtland Air Force Base in Albuquerque, New Mexico. I'm honored to

make these knives.

Some of the best knife stories I've heard come from the

owners of this knife. One was used to rescue a Navy SEAL

from a wrecked APC, one was used to pry the skin off a

damaged HELO. One was used to save a trapped PJ's life by

severing a nasty cargo net from a tossing tanker in the

middle of the ocean. One was used in a critical rescue

effort of a collapsed building, and several others have been

used to defend a life in CQC (Close Quarters Combat). Others

are at the ready, strapped to a PJ, during jumps in combat

and over the ocean.

I can't go where these knives do, but I'm thrilled to

know they are there!

Page Topics

PJLT with Tension Sheath

PJLT in Linen Micarta

PJLT CSAR Knife

Thanks Jay.

We all really appreciated that you took time

out of your day, as busy as you are, to let us come by and

check everything out. It was very impressive to see all the

work, skill and care that goes into the knives you produce.

I also wanted to express thanks for being so supportive

toward what were trying to do, and more so, the military in

general. We all thought that was really nice. I'm really

excited about this knife, just the plastic cut out today was

neat, I cant wait to see the finished product.

Once again thanks,

--N.F., USAF Pararescue

More

More about this PJLT

Jay,

Just wanted to drop you a quick line. I picked up the knife from fed ex last night

and everything is there. Your work is superb! This thing is very light and fast in

the hand I cant wait to get it into action. Some people think I am crazy for spending

so much on a blade, but in the end knives are worth every penny! Especially if you

carry one as your back up weapon and your primary cutting tool into an environment

where it must work. Thanks again for your superb work again! Great job!

Vic, US Navy

Since the PJLT is custom and handmade, it can be made in any size,

with any materials, finish, embellishment, and personalization that the

client desires. On this page, you'll see many different types of PJLT,

and I'll add more as they are made. Some useful options and accessories

should be considered for optimization of a custom knife.

- Blade features: I usually include a

top swage in the blade spine, though some knives are not

made with it. The swage decreases point penetration

cross-section, in other words, it makes a more pointed,

sharper point. Since the swage is not deeply ground

(like blade grinds or cutting edges) it does not

significantly thin the spine or weaken it. This makes

the PJLT blade able to pierce better, useful for CQB and

CQC use and defensive tactics. Some clients want the

maximum blade point strength available or they never

intend to use the knife in combat, so they omit the top

swage. The swage can be any length, and mine for this

knife are usually about half of the blade length or

half-length.

- Serration variations: I have several

variations of serrations that can be applied to the PJLT. See

all of my current serration types, geometries, and styles, plus

lots of information, details, and instructions on sharpening and

serration applications and limitations on my

Serrations page.

- Filework can be simple, complex, or

omitted altogether. Filework can increase the texture on

the blade spine and in the handle tang, and increase

grip potential as it sets the knife apart as an

original, handmade work. More about filework on my

embellishment page.

- Sheaths for the PJLT are usually

kydex, are also leather:

- Kydex tension sheaths are made

of double thickness (.125") thermoforming kydex (methylacrilate

and polyvinylchloride) formed over a welt-frame of

5052H32 corrosion-resistant, high-strength aluminum

alloy. They are adhesively secured with waterproof

bonding agents, lined to protect the cutting edge

with specialized epoxy based materials, and

mechanically bonded with either nickel plated steel,

blued steel, or stainless steel Chicago Screws. Most

of them have reversible die-formed 5052H32

corrosion-resistant, high-strength aluminum alloy

belt loops that are additionally sealed with

acrylic, and some have removable flashplates made of

machine-engraved lacquered aluminum or brass.

- Kydex Locking sheaths are

made of double thickness (.125") thermoforming kydex

(methylacrilate and polyvinylchloride) formed over a

welt-frame of 5052H32 corrosion-resistant,

high-strength aluminum alloy. They are adhesively

secured with waterproof bonding agents, lined to

protect the cutting edge with specialized epoxy

based materials, and mechanically bonded with either

nickel plated steel, blued steel, or stainless steel

Chicago Screws. They have all stainless steel

locking components and machine screws, for the

ultimate in corrosion resistance, suitable for

temporary submersion. Most of them have reversible

die-formed 5052H32 corrosion-resistant,

high-strength aluminum alloy belt loops that are

additionally sealed with acrylic, and some have

removable flashplates made of machine-engraved

lacquered aluminum or brass. More on a

special

page.

- Sheath accessories include

Sheath Belt Loop Extensions, the Ultimate Sheath

Belt Loop Extension, and Sternum Harnesses. More

information on those on a

special

page.

- Leather sheaths for the PJLT

are made of 9-10 oz. leather shoulder, hand-stitched

with polyester sinew, lacquered and sealed. These

may have tooling, inlays, engraving, or other

artistic components suited to the individual knife.

More on my Sheaths page.

Page Topics

More

More about this PJLT and Accessory

PJLT CSAR Knife

Ranger PJLT

PJLT Knife

PJLT Commemorative

More

More about this PJLT

Since making the PJLT is a custom affair, and since it is my most popular

knife, you'll see many variations of the PJLT on my site and some are featured below.

Some are artistic adaptations, some are derivatives of the original PJLT design,

adapted for Pararescue and professional use. This is a versatile knife

design, and I look forward to experiencing the evolution of the PJLT in my

future years. Please check back as I continually update the website.

Thanks most for supporting our military, rescue, and law enforcement

professionals who make it possible for us to love the life we live in

the United States of America!

Page Topics

Jay Fisher and Pararescuemen, SERE Professionals, c. 1996

More

More about this PJSK Viper

PJLT Instructor's

Engraved PJLT Dedication

PJLT/Patriot

PJLT Shank

PJLT Shank