Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Zosma" Texas Moss Agate Gemstone Handle

Jay Fisher - Fine Custom Knives |

|||

New to the website? Start Here |

"Zosma" Texas Moss Agate Gemstone Handle |

||

Thanks for being here. I believe that one of the most important things I can do as an artist, craftsman, and knifemaking professional is to educate. Here, on this website, you can learn more than on any other website in the world about how a professional, full-time custom knifemaker works, and have access to the very best knife information available. You can learn what making fine handmade and custom knives is all about, and how and why it's important in our modern world, as well as the world of the past and the future. You can discover the major and minor issues and solutions about knife problems, and you can find out what the most advanced knife users in the world are using.

I promise that if you read the entire website (this may take months), you will know more than the average person, more than the average knife owner, and even more than the average knife maker and knife manufacturer about the finest handmade, custom, and specialty knives available in the world today.

I live in an unusual world—the world of fine handmade knives. There are very few professional full-time knifemakers; it is a fairly rare profession. While there are many people who try their hand at making knives, or make knives as a hobby, there are only a relatively few of us who make knives for a living, and fewer yet who have done this for as long as I have (decades). You would be correct in thinking I'm very proud of this; it's not a vocation for the timid. It's a very physical, tactile, and full-contact profession filled with noisy high speed machinery, incredible heat, chemical exposures, and an insane amount of dust, sparks, and motion. It's high tech machinery, it's hammers and hand-files. It's complicated and sophisticated scientific cryogenic processing. It's brutally gripping and grinding rocks under the spray of cold water; it's accurately cutting tiny bits of metal under a microscope.

It's also about web development, publicity, accounting, travel, and materials acquisition. It's about research into the deepest recesses of our past, historical uses and styles, embellishment arts and emotion. It's about survival in the most basic of emergencies; it's about fulfilling the most extreme critical needs of the most advanced counterterrorism units. It's about accomplished restaurant chefs; it's about investment collectors.

Most of all, it's about sharing what I know and do with others including business-to-business and expert-to-organization consultation. The people I work for and consult with are the reason I'm successful, and the reason I have what I consider to be the greatest job in the world.

This website is available, for free, to anyone who will take the time to read it. While there are some parts that are restricted, most of the important information is here, 24/7, for anyone to indulge in. While it's not legal to copy and paste or use my writing without permission, the ideas I put forth—and all ideas, for that matter—are free to use, free to understand, free to share. Ideas are not protected intellectual property; only the presentation (writing and photos) of them is protected. I invite anyone to learn as much as they can about the very best fine handmade and custom knives here, and share this resource with others.

There is a lot of access to information on the internet. If you put the search term "best knife information" into most search engines, you will see plenty of references, websites, and advertisements. You'll see knife catalog sales companies giving out inadequate, simplistic, and largely sponsor-driven comments, presented only generally and with weak, sparse overviews of things like steel and alloys. These are very incomplete descriptions.

For example, a frequently repeated claim is that certain steels were "specially developed for the knife and cutlery industry." When you read that one singular comment, you need to know that the entire website is suspect. There are no steels specifically developed for the knife trade and industry, anywhere. Steel use is a tremendously large field, and the tool and die industry is colossal. All steels used for knives today are designed for other uses, and knives are made of these steels simply because knives are tools. Claims of special steels used for knives is an pathetic advertising ploy, and you'll see this repeated on Wikipedia (open source and not peer-reviewed) and on many other sites that are selling knives made of the very steels they identify. I hope that you can recognize this advertising technique, and I hope you understand that knives make up less than a fraction of 1% of steel sales and global applications.

The worldwide picture is revealing. What is the largest use and application of steel in the world? As of the latest recent data (WorldSteel.org), most of the steel is hot-rolled sheets and coils. Alloy tool steel production overall is less than 9% of all steel production and use, and the majority of that is stainless steel. For a real shock, know that of the 9% of steels that are alloy steels, only 1.3% of those are alloy tool steels. In the relatively tiny alloy tool steel market, the uses follow in this order, from highest to lowest amount: automobile and transportation, industrial pipe and tubing, followed by consumer goods, typically used to form plastics. This is why less than 1% of powder metal alloy tool steel sales are for knifemaking; most of the powder metal technology tool steels are used in plastic injection molding dies. In reality, only a tiny fraction of a percentage of steel is used for knives.

This is why no steel foundry is going to design steel exclusively for knives and cutlery. They are after a much larger, much more substantial market of the industrial, military, and manufacturing tooling fields.

This concept goes hand-in-hand with the concept that if there really were a far superior steel for tooling uses, all other steels would be replaced, and never made again. Any steel choice for any application is one of a consideration of many factors: wear resistance, toughness, corrosion resistance, strength, and cost. Here's a section on my "Blades" page that details some of the many different factors and properties that determine a steel choice for knife blade use.

Though there is a tendency to throw out steel data gleaned from advertising white papers (specification sheets and data sheets) supplied by steel sales companies, the best information about knives is not just limited to steel. Knives are also about geometry, force application, handle design, dedicated uses, exposures, longevity, and value overall. They are also about sheaths, wearing, mounting, and interfacing with gear and the environment they occupy. None of these factors are presented in the "best" knife information website recommendations, but you will see them described in detail here at jayfisher.com.

When you look for the best knife information, you are confronted with pages and pages of "buying guides." These are directed toward consumers—consumers who are in a hurry to have someone else quickly identify the "best knife." After all, they are not knife experts, knife makers, machinists, or tool and die makers, they are consumers. So they look for guidance in the oldest craft known to man: making cutting tools.

The sad thing is that the place they are looking for the best knife information is written by novice website developers and advertising departments, or put together by knife dealers, or written by career "writers" who write for a living, and have never actually made a single knife. These are all factory knife buying guides and not valid knife information, much less the Best Knife Information available. Because they pay search engine companies and internet promotion companies plenty for search engine optimization and placement, their sites are pushed to the front pages of search engine results. After a few pages of this advertising ("click here to win this Badass Knife of the Week") and you'll realize that very little intelligent, worthwhile information is available. But then, factory knives are cheap and common, so there isn't a lot to know about a very low-end product.

This is why I've written and offered so much on this very site. I can't possibly make and sell every person a knife, so this is not a factory advertising website. Since the beginning of this website in 1996, I've written hundreds of pages about real knives the very best knives available, about who uses them and why, about all the components, materials, and history, and about all the details that dealers, manufacturers, and other knifemakers don't bother to present and don't want you to know. I do this as a service to my community, as a source of facts and reason in a world flooded with advertising hyperbole.

I promise that if you read this website, you'll know more than any of them. And it's all free, 24/7, on any device that can display simple, clear, HTML code. Bookmark it as one of your favorites, come back often; new information is continually presented.

For those who seek specific, detailed, or expansive information and knowledge about their particular knife-related project, direction, or research, know that I offer Expert Professional Knife Consultation. This is how important clear, accurate, and directly related information and knowledge is available in my field.

There is an incredible, mind-numbing amount of misinformation, confusion, and outright lies about knives on the internet. Take a look at any discussion forum with educated eyes, and you'll see these mistakes and misconceptions on every single page. Take a look at any chef's or cooking forum, combat knives forum, and even general knifemaking forums and you'll see the same kind of unending errors, falsehoods, and uncertainty. Even successful knife-using professionals are confused about what a fine knife is, where they come from who makes them, and why they make them the way they do.

Where does all this confusion come from? In knifemaking forums and on many knifemaker's websites, it may help to understand who the people commenting are, and what their level of experience is. Most of them are simply hobbyists, hoping to sell their knives for a couple hundred dollars. This means that they do not make knives professionally, do not have their knives used by other professionals, and simply are participating for the camaraderie, fellowship, and limited scope of the venue. In doing so, the same type of information is passed around over and over, and, in being repeated so many times, takes on the appearance of proof, endorsement, and sometimes truth, though much of it is plainly incorrect.

This is because real learning takes time, effort, experience, and a reliable source, and most people are plainly lazy, not wanting to invest the time to educate themselves in what interests them. It's much easier to search out a quick and pat answer than to read, learn, and experiment through trial and error or through application and research. With the overwhelming amount of information available online, it's easy to get confused, and research skills are then essential.

Because nearly everyone has access to the internet, anyone can put out videos of their erroneous processes, claiming they are teaching others "how to." The worst one of these I've ever seen (now removed from YouTube) was the guy explaining how to mirror polish a factory knife blade. He had a high speed (3600 RPM) bench grinder motor fitted with a buffing wheel sitting on a work bench. The motor was not secured to the bench; it was held there by the weight of a 10 lb. dumbbell—yes a dumbbell—with one of the ends resting on the top of the motor and the other end on the bench. He had attached a 6" diameter stitched cotton buffing wheel to the shaft of the machine, and he had it spinning upwards, that is, with the closest part to him spinning up and toward his face. As he explained his setup, he apologized for the lack of mounting of the machine to the bench; he went on to casually lay the knife against the wheel. I can think of nothing more ignorant, dangerous, and stupid than this man presented, and he presented it as if this was what everyone did in order to polish a knife! One slip, and the knife blade becomes a 100 mile per hour missile headed for his face. One vibration and the motor dances out from under the dumbbell and off the bench, and travels around the garage mincing and pummeling everything in its path until it loses momentum. Ghastly, just stupid ghastly.

Perhaps you think that an accident can't happen with a spinning disc of stitched cloths (a buffing wheel), so let me enlighten you. I know of three serious accidents that knifemakers have had with buffing wheels, and in two cases, they were fatal. The last one sent a knife, high speed, into the knifemaker's heart. This was a long-term knifemaker, not some novice, so this shows how dangerous these operations can be.

Though not all information presented on the internet by non-professionals is this foolhardy and dangerous, there is plenty of it to go around. Missed process steps, misidentification of metals, incorrect use of metal types, lousy grinding and machining, horrible profiles and arrangements, total lack of realistic sheaths, lack of all accessories, and regurgitation of factory knife claims, beliefs from a century ago, and beliefs made popular by Hollywood movies and video games permeate the conversations. If examined closely, it would take years to just identify them, and many more years to educate one's path through the mess. For one simple case, please take a few minutes and read the topic "Example of Bad Outside Heat Treating" for clarity.

This is why it's not typically productive for professionals to post on such venues and to argue with people who clearly have limited knowledge and no experience in the field. While I've become involved from time to time when the ridiculous commenters about me or my own knives need a sturdy dose of reality, it's better to present these ideas here, where truly interested and intelligent people can learn facts based on experience and success, and make up their own minds. And they do. I have continual testimonials of thanks from people who are searching for reason, knowledge, and the education that this incredibly important part of my tradecraft and art offers, and this is why I continue this service aspect, defined here. There is such a great need for information, that I provide Professional Knife Consultation for people, organizations, and entities that absolutely need to know more.

Why some people won't take the time to learn about knives—with so much information available—saddens me. I wonder who they are, and why they should have a desire to learn about knives. For example, I question why an accomplished chef knows next to nothing about the number one tool in his toolkit. Do you?

I remember seeing a television show highlighting a very successful chef who had started several restaurants. In a shot of his kitchen, the chef was using a knife typical of most cheap and common chef's knife styles, with three rivets through the handle. This knife was different—it had several rubber bands wrapped around the middle of the handle—rubber bands! I can only assume they were there to either help him grip the handle, or to hold the handle scales onto the knife as they were coming off. Either way, I can only cringe at the sight of it, thinking of all the bacteria and contamination that the rubber bands could harbor—and rubber stinks. What happens to the rubber bands and the knife parts when bits and pieces fall off or come apart? Do they end up in the dishes he was preparing? It was very hard to consider this man the professional he claimed to be under the circumstances.

I suppose the same scenario could be applied to a warehouseman who handles and opens boxes all day. His knife is probably the cheapest, weakest, and most commonly available box cutter sold at any hardware store. So what is wrong with the picture when applied to the chef?

The warehouseman is not a highly accomplished professional preparing expensive meals for others; he's a warehouseman. The chef is supposed to be far and above others in his craft: an artist, a skilled, highly ordered specialist, in tune with all of his implements. The same chef may cook on a one hundred and twenty thousand dollar stove, use the best copper-bottomed stainless steel pans, and serve on the finest artistic china plates with elegant and scratch-free cutlery. But he uses a cheap, three rivet handled knife from China made of 420 stainless steel? Why, Lord, oh why?

This is my complaint. Does he not know of the fine knives that are available? After all, money is no object to the true pro. I can only conclude that he does not know. He simply is not aware of better, finer, and excellent tools that are available.

This has been a problem I've seen in this career from beginning it. People simply don't know that fine knives exist. And what they consider fine is actually based on concepts from the beginning of the 20th century or before!

When I regularly did knife shows and juried art shows, I was in continuous contact with thousands of people, the public, who were looking for knives, gifts, art, and tools. This meant (in one in one particular venue) seeing the faces of over 80,000 people in three days. The most often made remark was, "I can't believe knives like this exist!" The truth is most of the public has no idea that fine, handmade, artistic, tactical, hunting, and chef's knives exist in the world. They simply don't know.

Early on, I realized that part of my responsibility was to educate. The public, the soldier, the chef, the investor, and anyone who has even a slight interest in knives should know that guys like me are out here, available to make the knife that they may never have dreamed possible. I educated. I talked myself hoarse at knife and art shows, going over and over the same comments, questions, concerns, and explanations. I spoke to people on the phone, in person, in any venue I could. It was a very difficult way to educate because it is clearly one-on-one, and every conversation supplied information to only one person.

Then the internet came about. Here, I can write it down once, and post it for the public to see, any time they want, for free, in the comfort of their home, work, vehicle, or waiting room, or anywhere they have access to the web. They can read as much as they like, absorb or discard what they read, knowing that these words come from a very successful knifemaker who has a decades-long string of experience to back those words up. There are tens of thousands of new readers every month, millions of accesses to this website monthly, and I know that most people appreciate the plain, clear, and very detailed information presented here. I know that this helps me, my collaborative and family knifemakers, and other knifemakers in general.

This means that knifemaking and fine custom and handmade knives are in a rapidly growing world, striking out as the art form that is first a tool, and then a legacy creation. A lot has changed since I made my first knife in 1979, and it's exciting to see where this is all going. You can get a good picture of the growth and potential in looking over my Patterns page, where there are over 500 of my patterns, presented roughly in chronological order. If you are intuitive, you can see spurts and periods of certain types of knives that have been made and interest my knife community, and roughly gauge the direction of knives in general.

Because knives are so personal and because they are ingrained in our humanity longer than any other tool, instrument, or device, we have a special relationship with them. The foundation of that relationship comes from our family and our upbringing. There is a lot of focus on personal family ancestry, relationships, and origins, and this continues to be fascinating and formative in our own psyche. Knives play a pivotal role because every family must have knives to survive, if it's just to butter toast or cut up a vegetable. Boys and girls are often brought up to use and appreciate knives, and these knives ordinarily come from a parent, oftentimes a father or grandfather, mother or grandmother—from elders comes the knowledge about the knife and its use, materials, safety, and value. These important points are typically passed down verbally, and this is where the confusion starts.

No one wants to hear that their dad, grandfather, or mom was wrong in what they shared about knives, but nearly all of the misunderstandings originate this way. My own father swore that carbon steel knives were the best, simply because he had never seen a high alloy stainless tool steel knife blade. I can't help but think that he never fully appreciated the modern and highly superior properties of these steels simply because he had no access to them in his youth. He learned what he knew about knives from his dad, who learned from his.

This would be like your granddad telling you about the cars of the 1960's: how great they were, how nothing could approach them for power, style, and mechanistic efficiency. Then, reality seeps in and you realize that modern vehicles are more efficient, better built, more comfortable, safer, and some even have more power than the muscle cars of the past. You don't have to replace starters, alternators, coils, and plugs every 30,000 miles, and the drive trains last two to three times as long. Because we respect our ancestors and elders, we honor them by holding those past values in regard, reviving and promoting them if possible, and remembering only the good of them. This is an honorable thing to do, we are all deeply connected to our past, and to our loved ones.

Make your ancestors proud.

It's a great thought, but so many times, our information is flawed. Just like the old, heavy, hulking, fuel-hogging and maintenance-sponging vehicles of the past, early knives, carbon steel knives, three rivet handles, weak and flimsy sheaths and constant sharpening are also of the past. Our grandfathers never heard of a locking sheath, they never saw high vanadium content in steels. Powder metal technology was unknown, gemstone handles were simply a dream. They never heard of steels being sharpened by diamond hones. They never knew about mirror polishes, and the only hollow grinds they saw were on their straight razors. They were happy with aluminum fittings, rough wood handles, and constant scrubbing and oiling of blades. They would be amazed at what is available today.

I feel my ancestors would be honored to know that I've continued on the path they started, that my education was based upon their original interest and passion, particularly for knives. They wouldn't want me to cling to outdated, antiquated concepts of the old ways of my profession, and would want me to learn, grow, and improve upon the foundation they set. In my life and in my profession, this means continual education, study, and practice. This is how we evolve and this is how we excel.

"For the love of money is a root of all sorts of evil, and some by longing for it have wandered away from the faith and pierced themselves with many griefs."

--1 Timothy 6:10 New American Standard Bible (NASB)

It's okay to work for a living, and earn a wage for doing so. This is honest work. But to use lies and evil to misrepresent, in order to sell an idea or product is not honest, and it does our tradecraft, art, and science no good.

Probably the worst part about my profession is the incredible amount of lies, misunderstanding, and hype created by companies who advertise knives for sale. There are numerous places on this website where you can read and understand this, from my Business of Knifemaking page to my Tactical Knives page, from my Factory vs. Handmade Knives page to my Funny Emails pages: all of these have direct and specific misstatements, fabrications, and ridiculous notions originating from knife sales companies. You'll notice I said knife sales companies, not only knife manufacturing companies, and this is because so many businesses are selling something that they didn't manufacture, that they didn't make, and that they didn't even assemble. They, then, are sales companies, not manufacturers. And they will use any means they deem necessary to sell their products. This includes lying about performance, steel durability and hardness, and even handle materials. They carefully craft their words to infer things (like the American manufacturer who calls stabilized and laminated birch "cherrywood." It is not cherry, and not even really wood, but mostly polymer with a birch wood base (Dymondwood made by Rutland Plywood Corporation). They hope that by putting the words "cherry" and "wood" together, you won't notice that the wood is not cherry, but their neologism (new word) infers that it is.

Why don't they simply tell the truth? Because the truth is not so flattering to their product, that's why. It's a continuous game of misleading, misrepresenting, tweaking the words, omitting the limitations, and pushing the dream instead of clearly describing the exact knife.

What then, are the specific causes of misunderstanding about knives, generally?

So what is the problem here? It's simple. It's ignorance. And the only way to combat that is with information, with actively learning about knives and everything knife related.

Where does one go to learn about knives? The books that are in print are woefully dated, lacking in structure, lacking in historical references or modern applications. The DVDs and offerings on the internet are only for self-training, and are often published by people and makers who are not actually making the finest, most modern, most sophisticated knives available today. The people who are making these knives are far too busy to peddle how-to instructional videos.

Because you are reading this, you already know the answer; and a lot of it is right here. In addition, I encourage the purchase and study of historical texts for their historical value, for knives have been made a very long time. What was once considered a simple craft tool is now a sophisticated instrument, made of finest materials and costing thousands of dollars.

This is also the reason I'm writing a lengthy and long-term treatise on my particular journey to share what I have learned. The more I write, the more there is to write, and it may be an unfinished work when it's offered to the public, simply because of new advances made in materials, technology, and processes. So if you want to get a leg up on this subject, I recommend learning all you can from this very website; it has more to offer on the subject than any other singular professional knifemaker's website in the world.

If you are a person, organization, or entity that absolutely requires the very best current and specific information about modern knives, and it is necessary for safety, mission, or specific use requirements, I provide Professional Knife Consultation services. Take a look at the page, and contact me with specifics so I can help you make the critical decisions and choose the very best possible options for the very best possible results.

And thanks for being here!

The relationship of iron, carbon, and the alloy set is synergistic, with the performance of the whole being greater than the individual elements, in strength, hardness, wear resistance, heat resistance, corrosion resistance, and toughness, when properly processed.

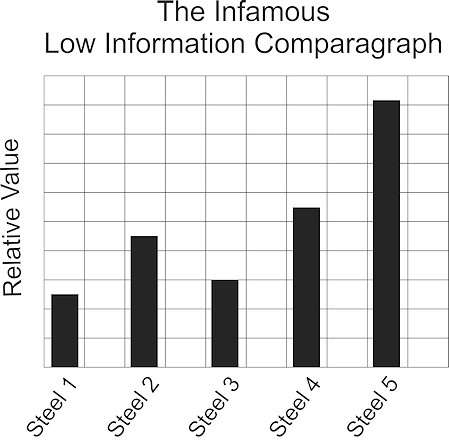

Graphs are great things, and in our eyes, we can quickly determine which item being graphed ranks the highest. Since the internet is all about finding information as fast as possible, why not just glance at a graph and instantly know which choice is best? The truth is, these are low-information, cleverly constructed, misleading and suspicious techniques to sell you an idea. Comparagraphs are advertising graphics and pictures, not meaningful, representative and scientific modes of information and presentation.

Are you surprised to read this? I'm going to make this very clear and once you read this section, you'll be able to instantly spot these advertising tricks, clearly distinguish advertising hyperbole from facts, and be able to associate the actual item being measured with its place in the cosmos. You'll understand why these tricks are used to get your belief, your support, and your dollar.

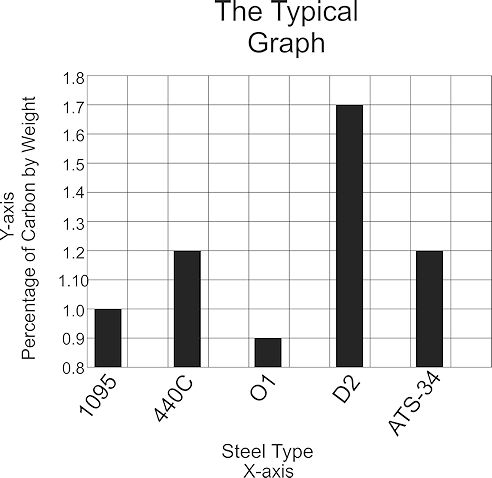

A real graph can be a great thing. A graph typically displayed in the knife and blade steel world is a called a bar chart, bar graph, or sometimes line graph. It uses horizontal or vertical bars to show comparisons among categories, types, or items. By the way, this is where the "compare" part of the made-up word "comparagraph" comes from.

In a real bar chart (not a comparagraph), the horizontal (X-axis) and vertical (y-axis) actually measure specific values. For instance, a valid graph comparing the carbon content of various steels will often have the steel types along the horizontal x-axis of the chart with the specific percentage by weight of carbon content on the vertical y-axis.

In this graph, you can see some concrete numbers along the Y-axis. The numbers are identified as the "Percentage of Carbon by Weight," and it's a pretty clear comparison. The various steel types are listed below the graph on the X-axis, as 1095, 440C, O1, D2, and ATS-34. It all seems pretty straightforward.

This is actually a horribly limited representation of the various steel properties, and here's why:

From this, you can see by only looking at one singular component (percentage of carbon by weight), an overall determination cannot be made with a simple bar graph. Yet, over and over, this is how people rate things. Could it be that they are so limited in their mind that they can only consider one singular aspect at a time? This is not how steels are measured, rated, or gauged on performance criteria. Clearly put, the relationship of iron, carbon, and the alloy set is synergistic, with the performance of the whole being greater than the individual elements, in strength, hardness, wear resistance, heat resistance, corrosion resistance, and toughness, when properly processed. And the geometry and processing is completely ignored. Remember, I'm only detailing the steel, and there is so, so much more to every knife!

If the simple bar chart is not the determinant factor of knife performance, usefulness, or value, what does this mean for the "comparagraph?" Hold onto your hat, because the comparagraph is the worst, most ridiculous, most deceiving, corrupt, and disgusting advertising and sales vehicle devised by man. Wow!

"Really, Jay?" you ask, "Isn't this a simple device to make basic comparisons?"

No. This is a contrivance created for one purpose only: to paint a particular item in a good light for the purpose of sales. It's directed at low-information readers, people who can't be bothered with actual numbers that mean things. Let's get into this, because it's clear that we not only need to stop limited graphs in our discussions of knives and steels, but we also need to call out the comparagraph for what it is, and force companies to stop using this deceiving contrivance to try to sell something. There are much better ways to describe steels, performance, and knives than a vague, deceptive, and made-up graphic. Read on, and you'll see what I mean.

If you look up the word "comparagraph," you'll find that there is no such thing, apart from documents using them and detailed advertising and promotional textbooks describing how to manipulate the minds of buyers by using a comparagraph ("Competitive Intelligence Review in Business Management and Advertising"). Seriously, these are atrocious things and using them screams out "advertising ploy based on constructed deception." In a way, they're worse than lies. At least lies are outright untruths, and may exist because of ignorance. A comparagraph is constructed solely for the purpose of directed deception, by omission, arrangement, selection, and visual drama.

A comparagraph has all of the faults and shortcomings that a bar graph has listed above: lack of wide specific representation, exaggerated spread of range for more dramatic display, no information on specific properties and their interactions in the entire alloy, no actual performance data, and no actual value data. This is bad enough, but it gets much worse:

By now you should be able to clearly see and identify the problem and issues with both incomplete graphs and subjective, made-up fake comparagraphs. Now that you have this distinction, you'll realize that the reason they are created is that someone is trying to sell an idea or product. That's it; that's all they are.

You'll never be taken in by them again, and others who read this and are educated will also know the folly of singular an subjective comparisons. You'll be able to laugh together at the steel companies, advertisers, dealers, and sales companies that use them; you'll be able to dismiss buying guide writers, forum posters, or posers who claim that these documents are of some value, when clearly they are not.

So where do you go to get the real information? Who is it that has the scoop on steel performance? I mention steel performance because these are mainly where both types of advertising presentation occurs. And there is so much more to knives than just the blade steel.

The best places to get information on various steel performance, use, and value are:

Just don't be hoodwinked by ridiculous, limited, and fake graphs and comparagraphs designed to sell a product.

Someone posted this question on my YouTube channel:

"Where can I find information on chromium carbide fractions per total carbide volume in different steels, ideally including pre/post cryo?"

Here was my answer: "Unfortunately, this is not as simple as it seems, since all steels vary tremendously by alloy and specific condition as well as treatment regime. Carbide volume is a highly researched topic, and the most current and valid information is found in research papers by scholars in metallurgy. Most of these studies are available (for a fee) from research gates, often with memberships. This is only reasonable, since it is very expensive and time-consuming to perform metallurgical and chemical analysis. I suggest that you detail the steel type and specific conditions and treatment, and then enter your information in a research gate for the most current applicable information on the particular steel you are interested in."

I want to go on a bit more, since this is too expansive for the YouTube format.

Knifemakers want information, and mostly this is available on the internet, but not always. Good information, trade information, can be very expensive and highly guarded. Take, for instance, the realm of heat treating. If a company or entity invests many thousands of dollars in heat treating and procedure, protocols and systems, analysis and improvements, are they expected to simply give this data away for free to help competitors? Of course not. This is how information can have extreme value in the modern world.

What many knifemakers are seeking is simple recipes: mix "A" with "B" and warm to "C" and then cool to "D" and your done. They don't often want to bother with real research in their own field. Knifemaking is not general metalwork; it's a specific, highly controlled process that has a very narrow field interest.

There are no massive tomes that reveal heat treating and specific carbide amounts, indexed to steel types, geometries, and specific knife shapes for every conceivable steel used in the tradecraft. If a company is making jet aircraft turbine blades for the military, you can be certain that these companies know the exact and specific contents of their metallurgy. They also are not going to furnish their competitors with their manufacturing process and guarded procedures. No such information reference exists in knifemaking. There isn't even a degree or certification in knifemaking, and there probably ought to be, since the safety of the knife user may be based on the knifemaker's ability to properly treat a blade!

Sure, some knifemakers have posted their recipes and procedures, but none of them is doing actual wear testing by abrasive methods, metallographic analysis using scientific methodology. For example, on one knife forum, one particular participant is accepting test pieces furnished by knifemakers to perform a toughness test. He doesn't know how the steel is treated, he doesn't know the exact chemical analysis and supplier of the steel, he doesn't even know when the steel was purchased or from who. He doesn't know how fast the steel was moved into cryo, how the cryo temperature was established and maintained, or even if it was. He just accepts bits of treated steel from makers for a "comparison." And this guy calls himself a knife metallurgist! In the universities I deal with, he would have failed his statistical analysis course the first test...

My point is that scientific testing is a highly, HIGHLY controlled process. All testing needs to be done with strict control and in an extremely narrow framework of process. Simply put, as many variables as possible must be eliminated to reach a specific conclusion. For example, if steel testing is done in heat treating, the amount of minutes a test piece sits at room temperature before cryogenic cooling takes place can change many characteristics in the steel metallurgy. In handling samples for testing, all of the samples must be treated exactly the same, at the same time, in the same place and exposure, with strict controls of the process. Otherwise, a finding does not have validity. Is the D2 steel tested developing more ferrite and cementite because of holding time at room temperature after initial quenching, or is it developing more ferrite and cementite because of a higher tempering temperature surging because the tempering oven door is opened too frequently?

If you think this can get very complicated very fast, you are right. Consider that most knifemakers think a two rivet-handle is good mechanical practice, and a sheath is simply a troublesome afterthought, and you'll wonder why they are worrying about grain bonding and carbide development in high purity alloys.

The answer is, as always, start with the manufacturer's (or foundry's) information on steel treatment, and if you have the time, money, and scientific interest, start making careful and considered adjustments to their recommended procedures based on performance and what you have learned. Document everything! Don't expect a recipe book to tell you that you need to have a maximum of 12 feet between your quenching apparatus and your freezing apparatus so that you eliminate any chance of the occurrence of quench cracking from the volumetric expansion caused by isothermal transformation of retained austenite into martensite during your stride from one piece of equipment to the next! And keep your strides smooth and fast, yet do not incur any wind from your travels...

On one of my Instagram posts, a guy made the claim that a knifemaking supply company was the source of all correct information regarding steel types, uses, and blade applications. His resource for knife blade steel value was the cost of the steel, presented in a comparagraph. Really? Do I have to go into this? Of course I do, because people need to recognize sales 101.

Before I get into this, if you think what you reading here is simply a singular knifemaker's sales website and topic, you need to go away immediately. I don't need to sell you, who are reading this, a knife. I don't research, write, and detail this information because I'm trying to sell somebody a knife; you can see from the website that I really don't need that. My main purpose in writing this is educational, because so little actual truth and logic is available in our tradecraft and art. Also, as you can probably guess, I absolutely love writing, talking, and detailing modern advanced knives, since this is my lifelong career and passion.

But a knifemaking supply company does need to sell stuff for knifemaking, continually, aggressively, at a low profit margin. This makes selling their main purpose.

Let's get into the "information" provided by knifemaking supply companies.

If you are a new knifemaker, chances are you have browsed, read, and purchased materials from these catalog companies. For the most part, they provide a straightforward service to guys who make knives, and offer some shortcuts to new makers who can't or don't make the actual pieces that go into their knives. The level of knifemaking is highly variable; some guys buy premade blades and only attach handles, some just pick up a tiny piece or two of stock there to use in a project. Some purchase polishes or adhesives, some utilize a catalog knifemaker's supply company to do their heat treating.

The information these companies supply is sparse, limited, and totally generalized. What would you expect from a company that peddles $15.00 knife blades to beginners? By the way, nobody likes being called a beginner, or novice, or newbie, but everybody starts somewhere, and that's okay. You can learn a lot from a catalog, as long as you recognize that they are simply trying to sell you a product.

When they get into steel properties, their information is extremely limited, highly condensed, and broadly generalized. Beyond this, the purpose of their information on steels is to sell the viewer a product. Because most of their customers are newbies, they have to simplify their descriptions and no details are offered. Much of what they present may be offered in the form of comparagraphs. If you've read the section on comparagraphs above, you realize how limiting, misleading, and ridiculous these charts and graphs are, yet they seem to be a mainstay of new or novice knifemakers, simply because new makers know little to nothing about steels. Few new knifemakers want to study to learn about carbide development in cryogenic processing; they don't want to learn about tetragonal crystalline structure of evolving allotropic conversions and transformation kinetics. They just want to get a little information on "what steel is best." They can't easily find this anywhere but on the catalog sites and hobbyist knifemaker forums.

Since every steel is different and since there are a thousand different ways to process steel, to manufacture steel, to develop the steel during processing, to shape the steel, finish the steel, and apply the steel, there is absolutely no way that a simplified chart can give any useful information! If you are a fan of these comparagraphs and insist that a company that sells catalog parts for making knives is the genuine authority on steel application and treatment, I beg you to think, just think about what you are reading right now.

Let's compare. Rio Grande Jewelry Supply is a great big company based here in New Mexico, and they supply jewelry making supplies all over the world. They have been around a very long time, they have an unbeatable catalog of both tools and findings. If you're not familiar with them, I encourage you to take a look. They don't pay me for mentioning them; I have no association whatever with the company other than being a customer of theirs. Rio Grande has extensive, meaty, and voluminous catalogs printed every year, and they have a substantial catalog website. In their catalogs, they have meaningful charts about standard practices, materials, and measurements.

Whoops! News Flash! In early 2021, Rio Grande stop publishing paper catalogs. They claimed that it was because they were "listening to their clients" about saving the planet by not using paper, but one has to question how many people they conveniently laid off by moving their catalog to online only. Could this be a cost cutting measure after a year of depressed sales caused by the pandemic in 2020? No, certainly not. They are listening to people who are demanding that they save the rain forests by not using any paper. Right. In any case, they still have a good online catalog.

No where, in their entire catalog structure, do they compare properties of the metals with generalized comparagraphs. They don't do this with gemstone, or with tools, or with applications. The reason is probably that they cater to actual jewelers, a wide range of types. There are jewelers who buy findings and buy a finished, polished stone, and stick them together and sell them. There are jewelers who start with a bit of wax, carve it into shape, cast the metal by lost wax process, and use tools to cut, lap, shape, grind, and finish stone and have complete creational and artistic process over their jewelry. Many are professionals, and don't need novice, generalized information about their tradecraft.

Compare Rio Grande's online catalog structure to what you see at a knifemaking supply company's catalog. Knifemaking supply companies have simple designs, blade blanks, steel billets and bars (all overpriced). You see generalized charts on things like the price of steel weighed against whether the steel is "low, medium, or high grade" and other such nonsense. You may even see the same discussion forums as everywhere else, occupied by largely anonymous hobbyists, claiming they are "knife aficionados" because they own two factory-made folding knives.

I'm not saying that you won't find anything of value there, but you probably would do good to consider the source, and what their standing is in the actual knifemaking community. They are there to sell their stuff, not to educate, not to give back to the knifemaking community, not as a resource for consultation, for metallurgists, for professional and military applications. To use one of their "comparagraphs" as a source of information in a foolish beginner's mistake. They don't even make knives!

One more helpful thing to new knifemakers. Do your research, because nearly every item you see for sale at these catalog websites can be made, purchased, or acquired somewhere else, for a lot less. After all, where do you think they get the stuff they resell? Yes, these are resellers, clearly and accurately described in business classifications of our country's official governmental tax codes.

Don't get your information from a reseller. Buy a few books, read some research papers, move beyond the fastest, easiest, most mindless chart you've found. And don't complain to the rest of us, who actually do know how to make knives, that you have the answer, until you actually do have the experience to produce it!

For the knife client, you deserve to know everything about your knife: where it comes from, how it is made, how it is processed, what attributes and limitations there are. The steel type shouldn't only be identified, but should also be detailed by application, geometry, and treatment. The knifemaker should answer every question you have, with intelligent, resourced and concrete specifics.

If a knifemaker tells you that he got his information from a generalized "comparagraph" chart, you should run the other way, clutching your cash. After reading this section, now you know why.

It's not surprising to find this type of site in searching for the best knife information, and for the most part, the people who operate these sites have good intentions. However, when claiming to be a source of legal, authoritative information, one needs to be very careful about what is presented as "fact," particularly when it's easy enough to determine laws as each state has them posted, by statute, publically on the internet.

I'm not trying to be difficult, nor am I trying to be a source of trouble and discontent. What I am doing is making sure that laws, statutes, and what constitutes criminal behavior is clearly and accurately identified. When an organization claims that it is the source of official trade information, and claims its goal is to educate, the general idea is typically that information presented there is correct. My point in exposing this is that this particular organization was not only misrepresenting the law, but they initially refused to consider that they were wrong, sending me a response that seemed to try to discourage the truth!

Thanks for taking the time to read this; it's a bit lengthy, but illustrates why this type of non-profit knife lobbying organization is clearly not the source of the best knife information.

Here's a copy of an email I sent to the "American Knife and Tool Institute" (AKTI). This is a a non-profit 501 (C)(6). C6 non-profits are classified in the IRS code as "business leagues, chambers of commerce, boards of trade, and similar organizations."

The IRS goes on to define in the 501 (C) (6) regulations:

"Reg. 1.501(c)(6)-l defines a business league as an association of persons having a common business interest, whose purpose is to promote the common business interest and not to engage in a regular business of a kind ordinarily carried on for profit. Its activities are directed to the improvement of business conditions of one or more lines of business rather than the performance of particular services for individual persons."

The AKTI claims to "Educate, Promote, and Inform." They receive their money through donations, auctions, and memberships, and they do not pay taxes as they are a non-profit. they are a lobbying organization, and the 501 (C) (6) status allows them unlimited spending on lobbying efforts.

It's probably important to know that nearly every one of their "Board of Regents" is a President, CEO, or manager of a factory knife company. With that, one might suspect that the individual knifemaker who makes handmade and custom knives is not their source of concern or focus. Simply put, factory knives are not the best knives, and this organization is made up of factory knife interests. By the time you're done reading this section, you might wonder how these companies could be participants selling prohibited knives, at least in the state of New Mexico. Are they breaking the law outright? Are they just innocent manufacturers whose products are distributed and sold illegally in New Mexico? Interesting, isn't it?

It's great to read that Improvement of business conditions in the field of knives is a positive goal, so imagine my surprise when I found misrepresentations on the AKTI website. In the interest of clarity, and as a professional, I wrote them:

On your definitions page, you claim:

"Comments on Daggers"

"A substantial numberof [sic] American jurisdictions prohibit the

possession or carrying of daggers. Among those states are Hawaii,

Massachusetts, Minnesota, Missouri, New Mexico and Iowa. However,

there is no rational explanation as to why governments should

prohibit daggers. Moreover, typically there is no guidance as to

whether any given object is or is not a dagger. The California

statutory definition is illustrative."

Just so you know, New Mexico is an open carry state, and there are absolutely NO laws prohibiting the possession or carrying of daggers. In fact, anyone can carry any type of edged weapon they please, in public places as long as one condition is met: it is not concealed.

New Mexico prohibits carry of any knife capable of injury from being carried concealed. If you have it in the open, firearms, knives, clubs, pipes, baseball bats: whatever one pleases can be openly carried on public property. And there is NO specific prohibition of daggers anywhere in our state. If you know of some law that has come up specifically about daggers, please do cite the actual statute. In fact, since your effort seems to be knife laws, it would be reasonable to cite every statute number in every place where comments like this are made. Then, there will be no confusion.

I can only guess that New Mexico's Criminal Code definition of "Deadly Weapon" may have been what was considered by whoever wrote this a "Prohibition." But please be clear. A definition of a deadly weapon is NOT a prohibition.

It's entirely normal and regular to see hikers, walkers, and runners armed in New Mexico with deadly weapons (including firearms) because we are an open carry state. You might ask why they are armed, and you'll get a lot of answers, but in my small town neighborhood, it's usually because of Pit Bull Terriers running loose that have been known to attack people.

The reason that I'm writing you is that I'm a professional knife-maker, and well-aware of statutes and limitations in our state, New Mexico. I'm not familiar with every other state's laws. If you make the claim that daggers are prohibited, you may open yourself up for some liability, as businesses like mine sell daggers regularly. This misinformation could be seen to prevent dagger sales, as people who read it may think it is the truth, and shop elsewhere, which hurts local businesses.

Since this is important, you may want to revisit the comments that are made about other states. Misrepresentation is a serious legal concern. You claim your goal is to educate, but by making a false claim, people who wish to purchase specific types of knives in states that do not actually have any kind of prohibition on ownership and carry (like New Mexico) are discouraged from buying these knives, hurting knife businesses of every kind.

Again, if there is some new restrictive law I don't know about, please do cite the statute. The police, military, counter-terrorism, and legal professionals who I make daggers for deserve the truth!

Thank you for your attention to this matter,

Jay Fisher

It took a while to hear back from this organization. Here is their response, from their Executive Director:

Mr. Fisher,

Thank you for taking the time and effort to express your concern with the information provided on our website.

I have asked two additional knife knowledgeable attorneys to review the New Mexico law and they concur that:

The introduction to the "dagger" definition does list states where there is statutory mention which restricts daggers, and New Mexico is one of them. It has a deadly weapon statute, 30-1-12, that provides among other things that daggers are a deadly weapon. NM statute 30-7-2 restricts how daggers may be carried.

The set of knife laws regarding New Mexico are spelled out on our website at https://www.akti.org/state-knife-laws/new-mexico/ and lists both of those statutes.

While common practice may differ, our effort is to present the knife law.

This is absolutely incorrect, and parses out two separate and distinct statutes in our state. One is about prohibitions and another is about deadly weapons, and the two are not the same. There is no "restriction" on daggers, and the information they listed on their site was not the truth. Why the Executive Director at the AKTI decided to respond by throwing in "additional knife knowledgeable attorneys," is a guess, since no actual attorney would use such a vague term as a "statutory mention." This is not legal language and not the law.

You can clearly see the issue in my response:

Hello; thanks for responding.

My legal authorities have agreed that your website statement is incorrect. Please remember, New Mexico is an “Open Carry” state, with no prohibitions on carrying any weapon on nearly all public property, as long as it is not CONCEALED.

Please read this carefully; while the wording may seem a bit ambiguous, carefully examining the sentence of the actual statute §30-7-2 will make it very clear. If you read it very fast, you may miss the word, or not apply it to the second phrase in the sentence. Here is the first part of the statute:

§30-7-2, Part A. Unlawful carrying of a deadly weapon consists of carrying a concealed loaded firearm or any other type of deadly weapon anywhere, except in the following cases:

The statute goes on to list the exceptions, but that is not the issue; the sentence in part A is the issue. Please look carefully at the word “concealed.” The word “concealed” applies to everything that follows it, in proper grammatical form. That means that the carrying of a deadly weapon is unlawful if it is CONCEALED. It’s really very simple. Whoever you have consulted has skimmed over this and not read it, or perhaps missed that bit of adjective placement that frankly, makes it clear that we are an open carry state! I assume your reference person is not from New Mexico and does not practice in New Mexico. Ask any New Mexico lawyer, law enforcement officer, attorney, or judge, and you’ll know instantly we are and always have been an open carry state.

“No law shall abridge the right of the citizen to keep and bear arms for security and defense, for lawful hunting and recreational use and for other lawful purposes, but nothing herein shall be held to permit the carrying of concealed weapons.”

Note again the use and placement of the word, “concealed.” And knives are currently considered arms. Clearly, we even have a bill of rights in place ensuring that we can carry arms for security and defense, as long as they are not concealed. This is very clear.

Even if you insist (incorrectly) that open carry does not exist in New Mexico, you have ignored the first part of your comment on your website:

"Comments on Daggers"

"A substantial numberof [sic] American jurisdictions

prohibit the possession or carrying of daggers. Among those

states are Hawaii, Massachusetts, Minnesota, Missouri, New Mexico and Iowa.

In this statement the AKTI website claims that daggers are prohibited from possession! This is incorrect. Our statute is very clear on what is prohibited from possession, and that is all spring, gravity, auto, or assisted opening knives including Balisongs and butterfly knives. Daggers are not, nor have ever been prohibited from possession. They are not mentioned in the prohibition law which is:

Unlawful possession of switchblades consists of any person, either manufacturing, causing to be manufactured, possessing, displaying, offering, selling, lending, giving away or purchasing any knife which has a blade which opens automatically by hand pressure applied to a button, spring or other device in the handle of the knife, or any knife having a blade which opens or falls or is ejected into position by the force of gravity or by any outward or centrifugal thrust or movement.

For the AKTI, this is a more concerning law. In our state, you can find auto knives for sale everywhere, including in Wal-Mart! This is a strange, unusual practice, and I would think that the AKTI resources would be better served correctly reporting that laws that are overly restrictive to knives are the problem, and this one is ignored, statewide. This is the real issue here in New Mexico; laws are created and not enforced. Presenting this on your website might illustrate how convoluted and confused our treatment of knives is (by type of pivot). I do agree that knife laws need close examination and modernizing; I hope that this is our goal from the standpoint of a professional knifemaker and knife law organization.

I’ll add once more that I believe it’s extremely important to clarify the comment on the AKTI website. Incorrectly claiming that daggers are prohibited from possession or carry could be seen as a litigious claim. People who read the AKTI website would think that daggers could not be made, purchased, possessed or carried in New Mexico, and this would directly impact the few knifemakers here in our state that rely upon dagger creation and sales as part of our business. It’s bad enough that we have an actual restriction on auto, gravity, and butterfly knives; please do not make this worse than it already is! I would like to recommend the AKTI for knife-related information, but currently, making misstatements shows a lack of integrity.

Thanks again,

Jay Fisher

The laws in New Mexico are very clear, and fairly simple. All I've really done here is to cite our actual laws, followed by why misrepresenting them is damaging to the very businesses (knifemakers) that the AKTI claims to support! Of course, there is not one actual knifemaker sitting on their board of regents, they are all knife manufacturer CEOs. The head of a knife manufacturing company is not a knifemaker; he is a CEO or manager.

After a bit of a delay, this was their response:

Jay,

I asked for an additional review and we have made some changes to the introduction regarding daggers and also change to the discussion on dirks that we had been working on.

Thank you

The entire definition string for daggers was replaced on the AKTI website with a long string of text citing California laws, restrictions, cases, and applications. There is no mention of New Mexico, or the other states they listed in the original claim. Truly, California laws can be restricting and confusing, but they have nothing to do with New Mexico. Thankfully, the AKTI had removed the misleading and incorrect comments from their website. I have no idea if what the AKTI website claims about California laws or any other state's laws is correct, or if it is just as wrong as what they claimed about New Mexico. I am not in the business of going through their website line by line, but I am concerned when my own state's laws are misrepresented, since it affects my business, profession, and career.

If you are a knife maker, knife seller, or knife owner, beware of this website. The AKTI is not the source of the best knife information. After this episode, I discovered they made the same incorrect claim about stilettos in New Mexico on their website...sigh. I wrote them again; they simply pulled the New Mexico name from their string of text.

Some countries have taken steps to outlaw knives with the idea of preventing knife crimes. In an effort to make the population safe, governments and organizations (particularly in Great Britain) have been lobbying and working for decades to remove the points from knives.

Yes, you read that right, remove the points. From knives.

Their claim is that no knife is needed apart from specialized tools (which can be regulated, controlled and accounted for), and kitchen knives. These parties believe that no kitchen knife needs a sharp, piercing point, only a rounded point and a cutting edge. This is rather humorous; try to cut up a melon with a blunt knife. Try to do any fine work with any knife that doesn’t have a point. Next, they’ll probably decide that the cutting edge itself is too dangerous, and require knives to be dull.

Statistics can be skewed in favor of a specific agenda, and this is done often in the political field. For example, several years ago, the President of the United States gave a speech and claimed that London hospitals were overwhelmed with the result of knife crime. In the article entitled "Trump's knife crime claim: how do the US and UK compare?" (Euronews, By Chris Harris 06/05/2018), a comparison was made about knife crime in the U.S. and the U.K.

The author was careful to compare "knife murders" per one million of population. He detailed five years, but this was not the issue. "Knife murders" country-wide were compared, but the President was only speaking about London.

Let’s look at some numbers with realistic details. The writer of the article only identified years 2012-2016. This is a misrepresentation. Knife crime in the U.K. has spiked dramatically in 2017 and 2018, and even more in 2019. (Ten charts on the rise of knife crime in England and Wales 18 July 2019, Danny Shaw Home affairs correspondent, BBC news). Even worse, as of 2021, knife crime in Britain had doubled in the previous six years, rising above 50,000 incidents in a one-year period in England and Wales for the first time in recorded history (Breitbart.com, Europe, by Kurt Zindulka, February 26, 2021).

So, using a graph that stops at 2016 is the first glaring error in the article by Harris. The article was written in mid-2018, so there is no excuse for omitting years 2017 and part of 2018, since the data up to that point was available. This is typical of misleading reporting, picking only the statistics that favor the viewpoint of the writer. There is no excuse for doing this, particularly since crime statistics can be easily searched and are highly detailed.

Using this limited data, the author then compares "knife murders" per one million of the population. The reason I emphasize the words “knife murders” is because the use of the term by the article’s author is a dramatic technique, meant to instill fear and drama, and is technically incorrect. Murder is only one form of criminal homicide, and homicide is defined as the killing of one person by another. Murder is a definite criminal act, while homicide can be criminal, accidental, excusable, or justifiable. This is a horrid misrepresentation of the data and the truth by the writer, since the data the author references is from FBI statistics for homicide, not murder.

To continue the attempt of his biased comparison, the author blatantly calls homicides in the U.S. “murders,” and homicides in the U.K. “homicides.” One can only assume that the more generalized word homicide lacks the shocking, violent impact of the word murder. In the writer's perspective, homicides are committed in the U.K., but in the U.S., murders are committed. This is obvious and blatant bias by the writer, obviously against the United States.

The chart that the writer includes suggests a fair comparison, but it is actually an attempt to distort the truth. The amount of actual homicides per one million across both entire countries varies extremely little at the time of the article.

Averaging the limited years, the author claims there were 4.96 homicides per million in the U.S., and 3.26 homicides per million in the U.K. This means that as a percentage of the population, only 0.000496% of people in the U.S. will be victims of knife homicide, and only 0.000326% will be victims in the U.K. Using these very statistics, based on a million people, the difference between the two countries is actually 0.00017%, which is incredibly, infinitesimally small.

Let’s take this a bit further. In the reference to the article, the United States President wasn’t referring to the entire country of Great Britain in his claim; he was referring to London. In the latest year available at the time of this writing, there were 169 knife homicides in London, which has a population of 8.9 million. This means that 0.0019% of people in London have been victims of a knife homicide. While this is a very low percentage, compare that to the United States overall where 0.000496% were victims of a knife homicide. From this comparison, you can see that it’s more dangerous to be in London than in the overall United States.

To compare:

Knife homicides per one million people in the U.S. overall: 4.96

Knife homicides per one million people in the U.K. overall: 3.26

Knife homicides per one million people in London, U.K. overall: 19

This is a big city problem.

There were over 912,000 crimes recorded in London in 2019/20, the most of any reporting year in the 2010s, and an increase of over 47,000 compared with the previous year. In New York City, murders soared almost 50% in 2020, but knife crime in both cities is almost exactly the same percentage.

This is a big city problem, and it hasn't always been so. Following this logic, what is so different now in the big cities? That's another topic, and it doesn't have anything to do with man's oldest tool. Large cities are more dangerous places to life. Grinding points off knife blades is unlikely to change the statistics, which are not attributable to the profile and shape of a cutting tool, but are about society’s greater issues.

Besides, it’s relatively easy to grind a point back onto a knife by rubbing it against a piece of concrete, plentiful in every city in the world.

You are reading the largest and most detailed website by any living knifemaker in the world.

I've often asked myself why I'm compelled to write so much about knives, and even more curious is my desire to make them! This is something that my Maker built into me, and sharing all of it seems important. If there were other sources that I could simply refer to, and a place I could send you, the person who is reading this, I would, but there is not any central source or clearinghouse for detailed, concise, and truly descriptive information about modern handmade knives, anywhere. Consequently, you are reading the largest and most detailed website by any living knifemaker in the world, and it's taken two decades on the internet to build it. If you know of any other singular knifemaker who offers so much information about modern handmade knives, please do contact me and let me know; he and I will have lots to talk about!

Like you, I'm interested in knives, intensely so, and I try to picture what you as a reader might value, the questions you may have, through my own eyes. Some of these are easily seen in the search engine metrics where I can actually read the query that Google uses to send people to my web site. When I started this profession, I had many of the same questions, not specifically related to the making of a knife, but details about knives in general. While there is a lot of information about knives today, most of it is piecemeal, biased, based on hearsay or myths, is anecdotal, or is flatly incorrect. To find answers, you'll have to do a lot of research, and then sift out the chaff to come to a clear understanding of the subject. What do I mean?

If you study knives, you'll quickly find out that most of the modern conversation about knives is centered on the blade. Not the blade shape, style, function, finish, or longevity, but on the steel type alone. Forums, bulletin boards, discussion topics, and advertising for knife sales is heavily slanted towards the steel type, and little else. The steel is the focus, the center, the be-all, end-all to knife value, it seems. Would it surprise you to know that this is simply not true, not even close? Many steels cut extremely well, and make great knife blades; I use over a dozen types myself. Each one has its own advantages and limitations, each one has a place in our modern world of metals. Sadly, when I read some of this commentary about blade steels, it is flatly incorrect. Sadder still is the practice of repeating misinformation to others, particularly new makers, young makers, and the public interested in knives.

The number one bit of misinformation or misguidance in discussing blade steels is the belief that the best performing and most highly valued knife blade steels are forged on an anvil in the open air. This is a practice that is many centuries old, is antiquated and, by necessity, uses low alloy, lower performing steels. The public, and worse, media (television and video) prefers the highly visual appearance of hot metal and sparks flying. I suppose this hearkens back to our prehistory, when staring into the fascinating light of a warm fire after a meal made us feel satisfied and fulfilled. Fire and sparks have a warm appeal; work is being done, heat is positive and reassuring. The visual experience of striking and heat together is powerful. Not so fascinating is an electronically controlled metal box, with a regulated and specific atmosphere, accurately applying heat in strictly managed circumstances, ordered and precise, hotter than any glowing steel on an anvil, doing the job, out of sight. Yet this is how the very, very best blades are made in our industrial, technological world.

The reality lies in the question; would you rather have a nice-looking campfire warming your home or a high-efficiency modern furnace? Sure the burning wood looks nice, but the smoke, the heat going up the chimney, the ashes, the draft... yet there is still a desire for home fireplaces. This is how I see hand-forged knife blades. It's a satisfying endeavor; I've done it myself in the past, but it makes a hugely inferior knife blade, particularly when measured against high alloy hypereutectoid and stainless tool steels, not to mention steels made and refined using vacuum induction melting, electro slag re-melting under pressure, and powder metal technology. You'll read on this website over and over that there are no blacksmiths in any machine shop, no one is hand-forging tool parts, pieces, and components, and you wouldn't want a hand-forged knee replacement, scalpel, or medical instrument that is not corrosion resistant or stainless steel. You wouldn't want a hand-forged turbine shaft on the aircraft you are flying, and you wouldn't want a hand-forged crankshaft in your car's engine. Yet, year after year, I'm contacted by media and production representatives hoping for a new knifemaking show, based on a guy hammering metal and sparks flying, with a lot of conflict, argument, hopeless competition, and embarrassment. The media and production firms are not interested in seeing modern, controlled atmosphere furnaces, cryogenic processers, and machine grinding techniques, even if all done by hand, because, like fireworks on the fourth of July, it's all about the visual appeal and the quick optic bite.

The true conflict with reality is brought to light when a professional knife user or collector of the finest handmade knives simply wants the best blade possible. If he reads and studies and researches his tools, he quickly finds out that the very best steels made today are available to him, but they are not easily and simply forged, ground, and finished. This is direct contradiction with the popular image of knives and knifemaking, particularly when fueled with the mystical entertainment media that fantasizes knives, swords, daggers, and cutting tools and weapons. This direct conflict is one of the reasons I am determined to share these truths, so that people who want the very best are educated as to what is available.

That's just the blade, and there is so much more to every single knife! What about handles, fittings, sheaths, and accessories?

This is why I'm compelled to share what my clients, what the truly interested person wants and needs to know about modern handmade knives. The people who read these pages don't need to buy from me (chances are that they won't, since I'm limiting my work and am years in backorders), but they do deserve to know some clear realities about knives from the perspective of someone who is and has been in the field for decades. They can choose to ignore it, follow up with research, or embrace any part of it; the important thing is that it's available to read, and that is something that didn't exist when I started in this field, and doesn't exist in most other knife domains. You deserve the right to consider it, and I thank you for your interest in the field I love.

Now the question of why me.. Please understand that I've been making and selling knives for a very long time. I made my first knife in 1979, sold my first in 1980, made knives as a part time knifemaker until 1988, when I went full time into knifemaking as a professional knifemaker. This is and has been my sole source of income for decades, and I've made and sold thousands of knives in my career. Many of these were made with the direct input of the professional knife user, for the most serious of knife use (in combat, rescue, and counterterrorism). Many were made for professional knife users, restaurant chefs, game outfitters, ranchers, horsemen, and guides. Many were made for collection and use, and all have maintained or increased their value over time. Every single knife I made was made by hand, one part at a time, and nothing has been farmed out, outsourced, or premade, in any way. I've made every knife to the best of my ability, using the best processes and highest potential my clients could afford.

You could say that my experience has been the same as other full time professional knifemakers, though you would be hard-pressed to find very many of them. It's a rare art, trade, craft, and science, no matter how many hobbyists try it on. One thing that I try to excel in is constant improvement of my work, skills, knowledge, and application in my field. Most established makers simply reach a certain level and make repetitive works. I'm constantly researching, learning, growing, and presenting, like the very text you are reading now.

This is why I believe I am obligated, am determined, and am compelled to share with you what I know about my field. I know of no one else who is driven to educate and explain this way, so if I don't do it, who will?

I love facts. Distinguishing the truth when there is so much misinformation, so many ridiculous claims and farcical knife presentation can be difficult, because we live in a world that generally knows very little about knives. This is silly, because we live in the greatest age of information and record that has ever existed in mankind, and the knife has been made longer than any other instrument in history!

For some reason, people get hoodwinked, confused, or buy the myth and mystical perceptions of the science of materials. They've seen references to the magical power of stones, so it must be true, right? They've seen red-hot knife blades hammered in some crude television contest of forging that was state of the art in the early 1800s, so this must be the way the best knives are made, right? How sad. By the way, where is the contest for the best hand-forged turbine blade? The best hand-forged ball bearing, the best hand-forged valve seat or helicopter gear? Why is there no blacksmith in any machine shop?

Simply put, the very best modern knives are a product of modern materials, modern machining, modern processing, and modern outfitting and accessory creation.